Flat Roof Education

Flat roofs, or "low-slope" roofs, are commonly found on commercial and industrial buildings around the world. They maximize space in structures that need to contain large mechanical units. The National Roofing Contractors Association defines a low-slope roof as having a slope of 3-in-12 or less. Flat roofs typically consist of a Single Ply roof system or an Asphaltic roof system, and are very different from residential roofs.

Commercial and Industrial flat roofs require a high level of expertise and workmanship to be installed properly and reach their serviceable life. Given the magnitude of what is protected by the roof in commercial spaces, it is crucial that you choose the best system for the building type and location, and ensure that it is installed correctly by a certified flat roofing contractor.

Over 80% of flat roofs are replaced prematurely due to lack of preventative maintenance and incorrect installation.

Commercial and Industrial flat roofs require a high level of expertise and workmanship to be installed properly and reach their serviceable life. Given the magnitude of what is protected by the roof in commercial spaces, it is crucial that you choose the best system for the building type and location, and ensure that it is installed correctly by a certified flat roofing contractor.

Over 80% of flat roofs are replaced prematurely due to lack of preventative maintenance and incorrect installation.

-

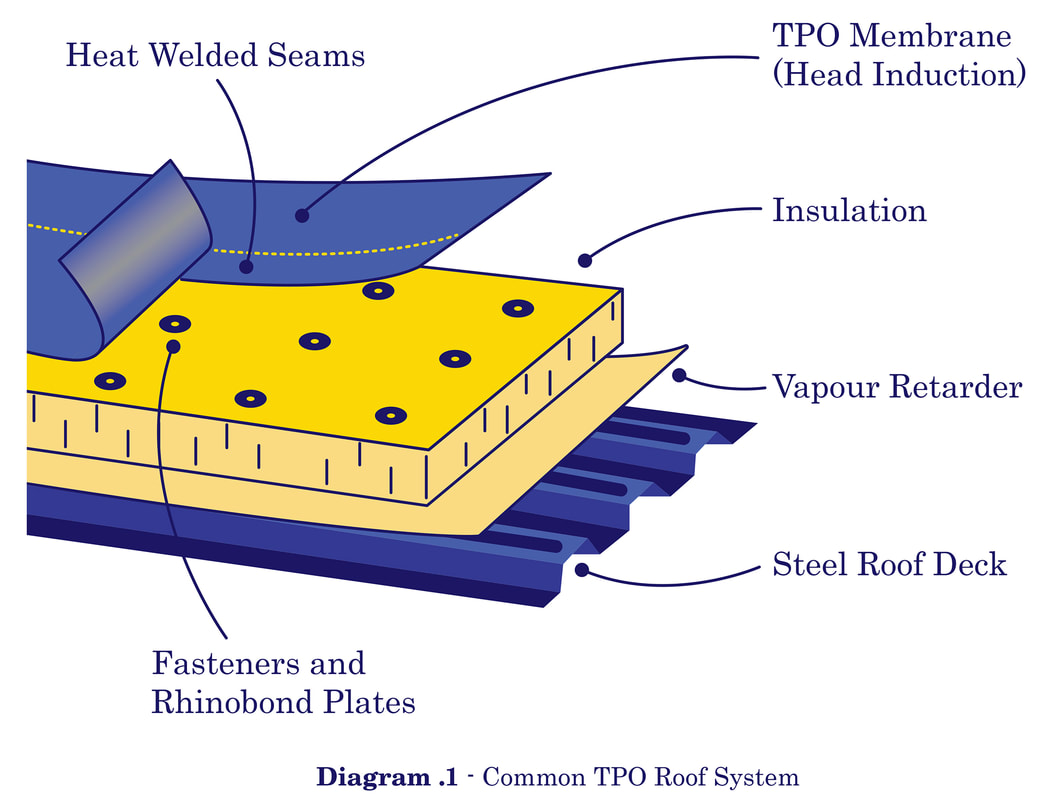

TPO (SINGLE PLY)

-

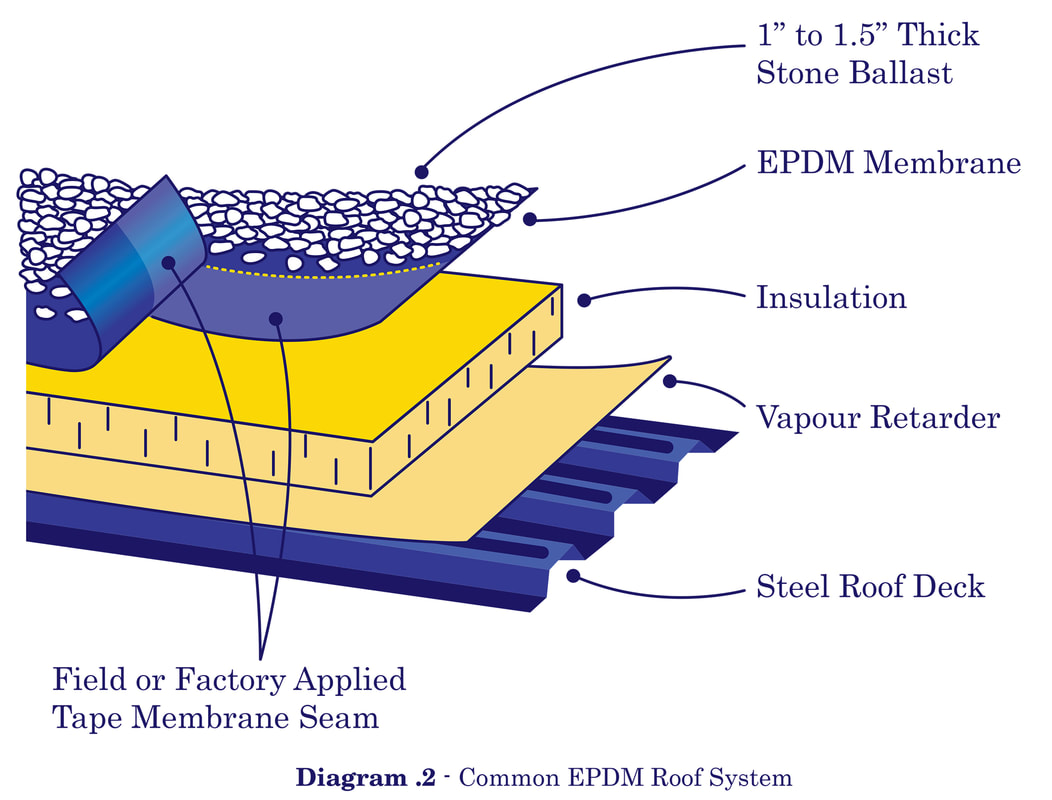

EPDM (SINGLE PLY)

-

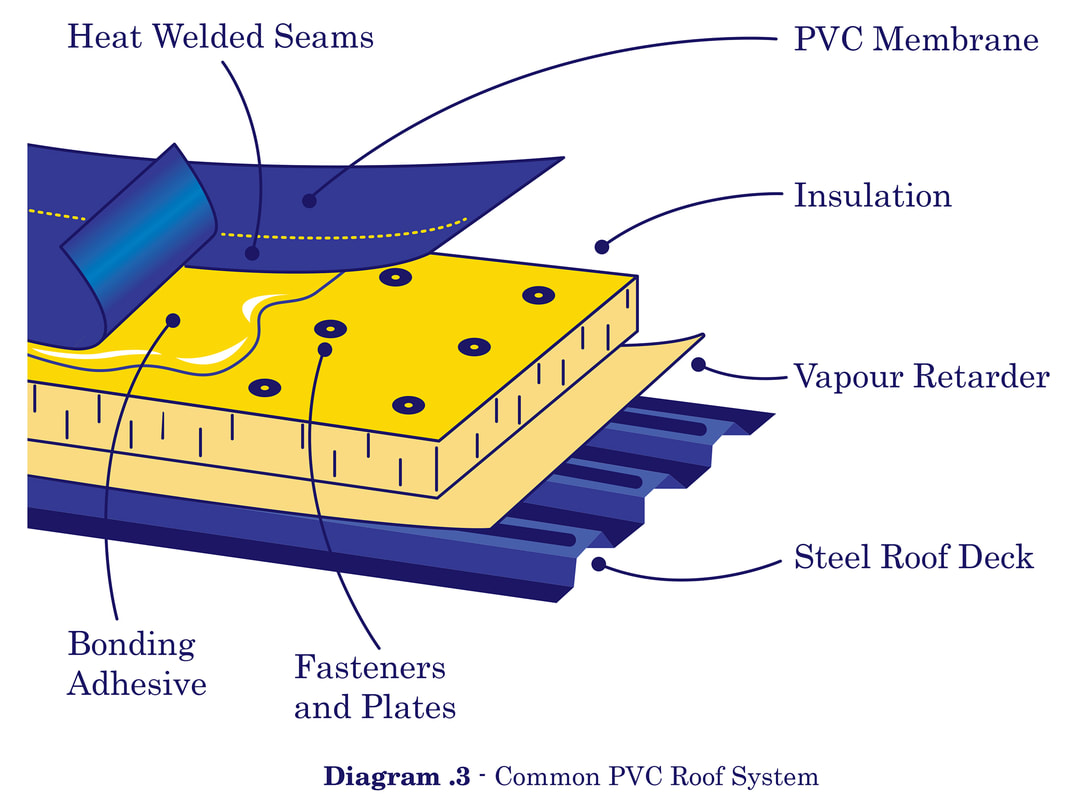

PVC (SINGLE PLY)

-

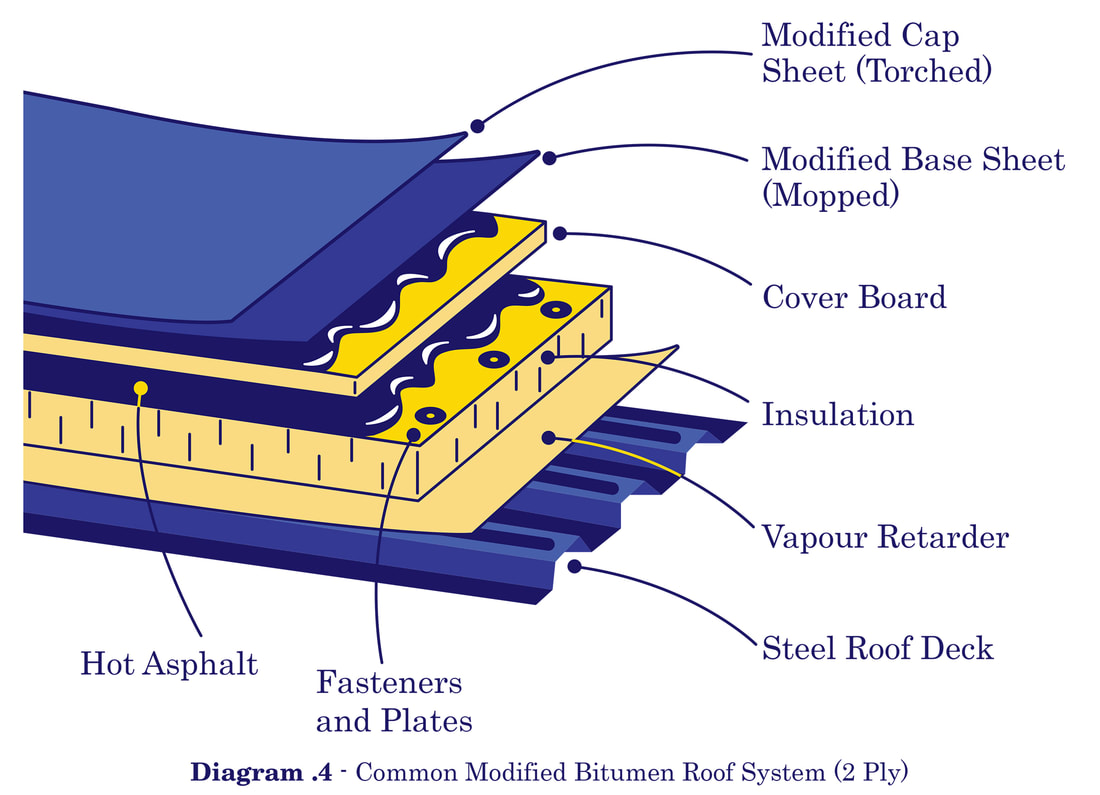

MODIFIED BITUMEN (2 PLY)

-

BUILT UP ROOF (4 PLY)

<

>

|

The first sheet was installed in 1986 and today TPO roof systems are the fastest growing commercial roof membrane on the market. Thermoplastic Polyolefin (TPO) is a single-ply reflective roofing membrane made from polypropylene and ethylene-propylene rubber polymerized together. It covers tens of millions of square meters on roofs worldwide.

Common Applications

Common thicknesses range from 60mil to 80mil membranes. Industry Standard colours range from White to Tan to Gray. Custom colours available upon request. Life Expectancy ranges from 15 - 25+ years depending on preventative maintenance by a certified flat roofing contractor. Pros:

|

Common Building Uses:

Manufacturers we recommend: Carlisle, Firestone, GAF |

|

EPDM, also known as Ethylene propylene diene monomer, is a versatile, synthetic rubber roofing membrane. It has been used on commercial roofs for over 50 years and over one billion square feet is installed annually worldwide. Originally used as pond liner, the EPDM membrane has proven to be one of the most reliable roof systems available today - it is highly economical, extremely flexible, and weather resistant. With a potential life expectancy of up to 50 years, this alternative is hard to ignore.

Common Applications

|

|

Common thicknesses range from 45mil to 90mil membranes.

Industry Standard colours are Black or White. Custom colours available upon request. Life Expectancy can range from 20 - 30+ years depending on preventative maintenance by a certified flat roofing contractor. Pros:

|

Common Building Uses:

Manufacturers we recommend: Carlisle, Firestone |

|

Polyvinyl chloride (PVC) is a trusted membrane that has provided decades of waterproofing protection in Europe and North America. PVC is popular for its dependable, heat-welded seams; high reflectivity; superior physical attributes; and resistance to ponding, chemicals, grease, fire and punctures. That being said, it can be one of the more costly roof systems to install.

Common Applications

Common thicknesses range from 48mil to 80mil membranes. Industry Standard colours range from Gray to Tan to White. Custom colours available upon request. Life Expectancy ranges from 20 - 30+ years depending preventative maintenance by a certified flat roofing contractor. |

|

Pros:

|

Common Building Uses:

Manufacturers we recommend: Carlisle, Sika, GAF |

|

In the early 1960's, a Modified bitumen roof system was introduced by leveraging the proven performance of BUR and adding roof wear layers or "cap sheets" that are polymer reinforced for strength and durability. It can be installed with the common torch method, asphalts, cold adhesives, and self-adhered. A standard SBS Modified Bitumen roof system is a 2-Ply system applied in rolls that overlap. These membranes are an innovative modification of the classic BUR system, eliminating more than two plies required to complete the membrane. This reduces labour and material costs.

Industry Standard colours range from Black to Brown to White. Custom colours available upon request. Life Expectancy ranges from 10 - 20 years depending preventative maintenance by a certified flat roofing contractor. |

|

Pros:

|

Common Building Uses:

Manufacturers we recommend: Soprema, IKO |

|

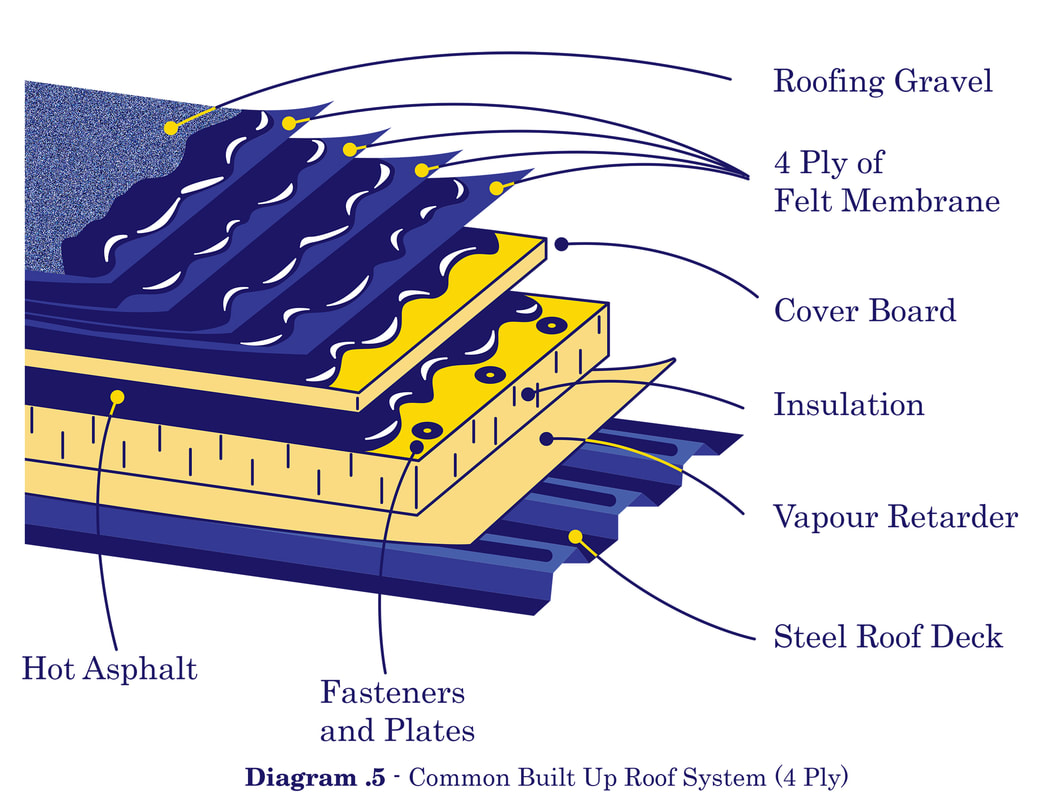

Also known as BUR or "Tar & Gravel," Built Up Roof systems have endured for over 100 years. They are generally composed of alternating layers of bitumen and reinforcing fabrics that create a finished membrane, followed by a top layer of embedded gravel and a flood coat of asphalt, then loose gravel to complete the system. This is designed to protect the roof membrane from traffic and UV rays. Built-up roofing (BUR) was the most common type of flat roof type until single-ply roofing and modified Bitumen was invented.

Industry Standard colour is generally black with Gray/White Gravel on top. Custom colours available upon request. Life Expectancy ranges from 10- 15 years depending on preventative maintenance by a certified flat roofing contractor. |

|

Pros:

|

Common Building Uses:

Manufacturers we recommend: Soprema, IKO |